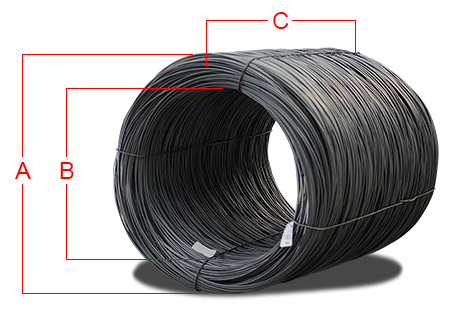

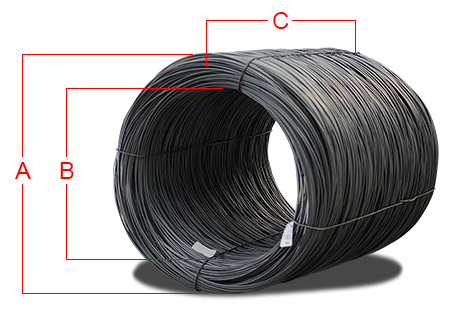

Semi-finished metallic products in the form of coils, manufactured by the process of hot rolling, used for cold drawing of round sections.

| Wire Drawing | |

| SAE1005 |  |

| SAE1006 | |

| SAE1008 | |

| SAE1010 | |

| Welded Wire Mesh | |

| SAE1008 |  |

| SAE1010 | |

| SAE1012 | |

| SAE1015 | |

| Cold Drawing and Peeling | |

| SAE1018 |  |

| SAE1022 | |

| SAE1026 | |

| SAE1030 | |

| SAE1035 | |

| SAE1040 | |

| SAE1050 | |

| Spring Steel and Steel Ropes | |

| SAE1045 |  |

| SAE1065 | |

| SAE1070 | |

| Welding Electrodes | |

| S1 |  |

| SG2 | |

| SG3 | |

| Bolt and Nuts | |

| SAE1006C |  |

| 17MNB3 | |

| 20MNB4 | |

| 23MNB4 | |

| 27MNB4 | |

| 30MNB4 | |

| Forging, Cold Drawing and Peeling | |

| C18 |  |

| C35 | |

| C40 | |

| C45 | |

| C50 | |

Ribbed steel reinforcement in coil form manufactured by the process of hot rolling for use in concrete structures.

Ribbed steel reinforcement in spool form manufactured by the process of hot rolling for use in concrete structures.

Reinforcing steel, being weldable or non-weldable, placed in the concrete in order to offset the tensile and shear stresses in the reinforced concrete structures, manufactured and delivered as finished products in the form of bars, coils and de-coiled bars.

Diameter Ø : between 8mm and 40mm

Length : cut-to-size between 6m and 18m

Bundle Weight : min 1000 - max 3000kgs

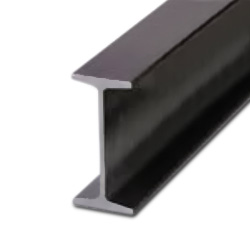

Structural steel sections manufactured by the process of hot rolling in certain cross sections and sizes, used in many areas such as construction, machinery, agriculture and energy industry, conforming to international quality standards and providing such advantages as mountability and high strength.

| NPU / Channels | ||

| Height: | Between 50 mm and 400 mm |  |

| Typical Lenght: | 6 or 12 mt | |

| Lenght Tolerance: | -0/+100 mm | |

| Quality: | S 235 JR or S 275 JR | |

| Production: | Between 80 mm and 160 mm | |

| Commercial Product: | Between 180 mm and 400 mm | |

| NPI / Beams | ||

| Height: | Between 80 mm and 450 mm |  |

| Typical Lenght: | 6 or 12 mt | |

| Lenght Tolerance: | -0/+100 mm | |

| Quality: | S 235 JR or S 275 JR | |

| Production: | Between 100 mm and 160 mm | |

| Commercial Product: | Between 180 mm and 450 mm | |

| HE A/B / Beams | ||

| Height: | Between 100 mm and 1000 mm |  |

| Typical Lenght: | 12 mt | |

| Lenght Tolerance: | -0/+100 mm | |

| Quality: | S 275 JR | |

| Production: | - | |

| Commercial Product: | Between 100 mm and 1000 mm | |

| IPE / Beams | ||

| Height: | Between 100 mm and 600 mm |  |

| Typical Lenght: | 12 mt | |

| Lenght Tolerance: | -0/+100 mm | |

| Quality: | S 275 JR | |

| Production: | - | |

| Commercial Product: | Between 100 mm and 600 mm | |

| Angles | ||

| Height: | Between 40 mm and 120 mm |  |

| Typical Lenght: | 6 or 12 mt | |

| Lenght Tolerance: | -0/+100 mm | |

| Quality: | S 235 JR | |

| Production: | Between 90 mm and 120 mm | |

| Commercial Product: | Between 40 mm and 150 mm | |

Bright Steel is produced from its own raw materials, offering a wide product range that includes structural steels, carbon steels, alloy steels, and free-cutting steels. Advanced technologies such as ultrasonic internal crack inspection and Eddy Current surface crack control ensure superior quality.

In our Bright Steel facilities, we use modern and highly precise technologies to ensure exceptional quality:

Cold Drawing: Diameter range 5-30 mm, length 3,000-7,000 mm.

Peeling: Diameter range 15-105 mm, length 3,000-7,500 mm.

Grinding: Diameter range 10-60 mm, length 3,000-7,000 mm.

Steel mesh is a material created by binding iron or steel wires together in a parallel grid pattern. It is produced by cold-drawing and ribbing steel, making it widely used in the construction industry for enhancing the strength and durability of concrete.

Aggregate is a manufactured product derived from the crushed and sieved by-product of steel production in Electric Arc Furnaces.

Areas of Use

Concrete

Asphalt

Road fill

Constructional fill